A matt non-reflective finish produced by cold rolling followed by annealing and descaling. The dull finish may result from the picking operation or rolling on dull rolls.

Available in 304 / 409.

A bright, moderately reflective cold rolled with the annealed and descaled coil receiving a final light pass through polished rolls. 2B is the most commonly used surface finish.

Available in 304 / 430 / 201 / 409 / 410 / 316.

A bright annealed finished approaches a mirror-like appearance. The final appearance is developed by a single light skin pass through a cold mill over highly polished rolls. Typically uses include appliance components, cookware, food processing equipment.

Available in 304/430/201/410.

NO.4/NO.3 finished is a general purpose polished finish widely used for restaurant equipment, ship fronts and dairy equipment. Following initial grinding with coarse abrasives, final finishing generally is done with abrasives having a particle size of approximately 120 to 150 mesh.

Available in 304/430/201/316.

NO.8 finish, the most reflective finish that is commonly produced on sheet, is obtained by polishing with successfully finer abrasives and buffing extensively with very fine buffing rouges. NO.8 is most widely used for architectural parts, small mirrors and reflectors and for press plates.

Available in 304/201.

Condition and finish commonly preferred fir corrosion resisting and most heat resisting applications. NO.1 is commonly used for raised angular rolled onto the surface to provide skid resistance.

Available in 304/430/201/410/316.

It's a semi-dull finish with uniform grain, which is obtained using finer abrasives than No.4/NO.5/NO.6. This finish has smooth, soft and exquisite grains which has a low level of reflectivity and unidirectional texture.

Available in 304/430/201/316.

Hairline is a two-step abrasive polished finish with superior matching characteristics. It’s designed for architectural applications. It boasts a more linear appearance than traditional #4 polish, which means it lends itself to repair and blending in the field. #6 Hairline is suitable for coping, trim, elevator cabs, and more. Can be coated with anti-fingerprint coating for interior use.

Available in 304/430/201/316.

| Grade | Finish | Thickness(mm) | Ranges of width (mm) | |||

| 1000 | 1219 | 1250 | 1524 | |||

| 430 | 2B | 0.3 - 3.0 | ||||

| BA | 0.3 - 2.0 | |||||

| HL/NO.4/SB | 0.3 - 3.0 | |||||

| 304 | No.1 | 2.5 - 12.0 | ||||

| 2B | 0.3 - 3.0 | |||||

| BA | 0.3 - 1.5 | |||||

| HL/NO.4/SB | 0.3 - 3.0 | |||||

| 316L | No.1 | 3.0 - 12 | ||||

| 2B | 0.5 - 3.0 | |||||

| 201 (Ni >1%) | No.1 | 2.5 - 6.0 | ||||

| 2B | 0.3 - 3.0 | |||||

| BA | 0.3 - 1.5 | |||||

| Thickness (mm) | Width (mm) | Length(mm) | PE Coating | Paper interleave |

| CR 0.3 ~ 3.0 | 1000 | 2000 | ||

| 1219 | 2438 | |||

| 1250 | 2500 | |||

| 1500 | 3000 | |||

| 1524 | 3048 | |||

| HR 3.0 ~ 6.0 | 1000 | 2000 | ||

| 1219 | 2438 | |||

| 1250 | 2500 | |||

| 1500 | 3000 | |||

| 1524 | 3048 | |||

| HR 8.0 ~ 50.0 | 1219 | 2438 | ||

| 1500 | 3000 | |||

| 1524 | 3048 |

| Length(mm) | Width Tolerance (mm) | Length Tolerance (mm) | Diagonal Tolerance (mm) |

| 400~999 | ± 0.01 | ± 0.3 | ≤ 0.5 |

| 1000~2438 | ± 0.01 | ± 0.5 | ≤ 1.0 |

| 2439~3658 | ± 0.01 | ± 0.8 | ≤ 1.0 |

| 3659~6000 | ± 0.01 | ± 1.0 | ≤ 1.0 |

| Thickness(mm) | Min. width(mm) | Thickness(mm) | Min. width(mm) |

| 0.3 | 10 | CR 1.5 | 35 |

| 0.4 | 10 | CR 1.8 | 35 |

| 0.5 | 10 | CR 2.0 | 35 |

| 0.6 | 10 | CR 2.5/HR 2.5 | 35 |

| 0.7 | 10 | CR 3.0/HR 3.0 | 35 |

| 0.8 | 10 | HR 4.0 | 35 |

| 0.9 | 10 | HR 4.5 | 35 |

| 1.0 | 10 | HR 5.0 | 50 |

| 1.2 | 35 | HR 6.0 | 50 |

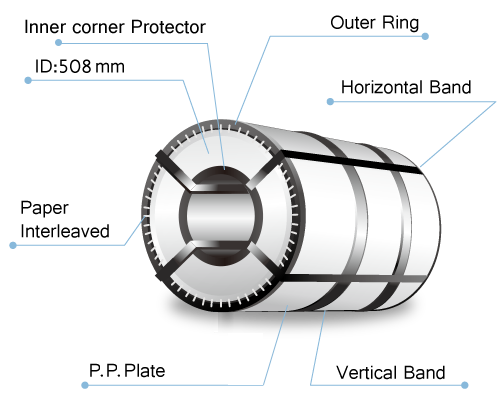

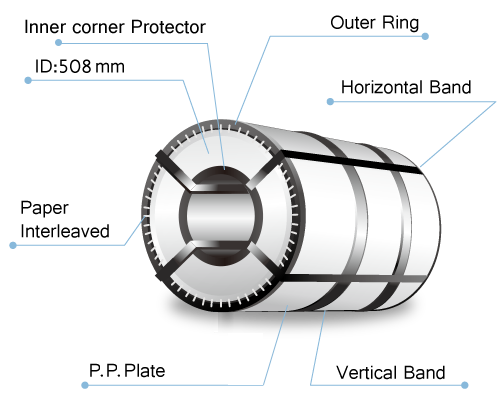

Exporting packages of S-More stainless coils are strongly protected by water-proof cover and P.P. plates. Between each layer, there is a paper interleaved or Protecting film, ensuring 100% dry condition.

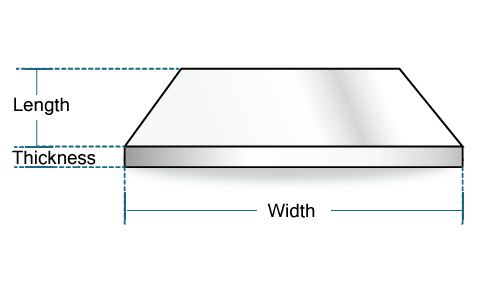

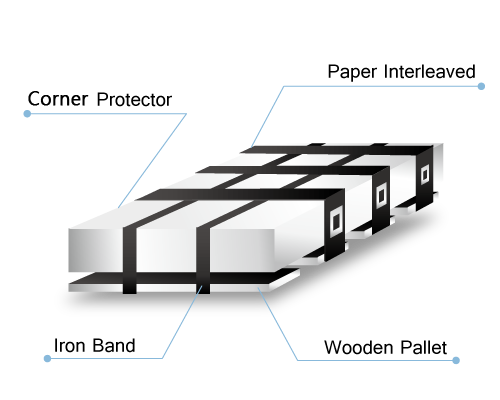

Stainless sheet is topped layer by layer on wooden pallets and cover by water-proof plates. Between each layer, there is a paper interleaved or Protecting film, ensuring 100% dry condition.

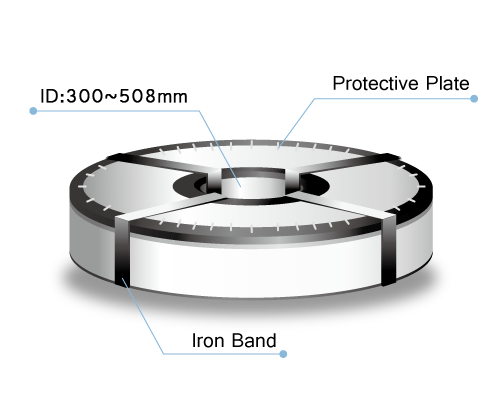

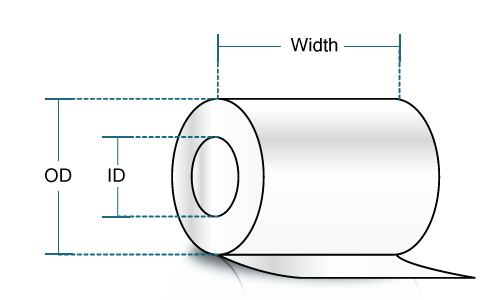

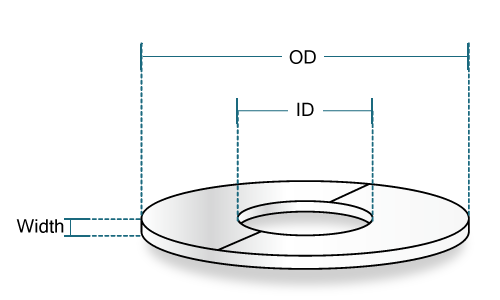

Customized stainless strip is fasten by iron bands. Horizontal and Vertical packages are available. Inner diameter from 300 to 508 mm for customers’ selection.